Winding is a critical process in the manufacturing process. It can roll certain materials such as metals, plastics and fibers into rolls or coils of different shapes, which can be used to manufacture various products such as aircraft, automobiles, furniture, electrical appliances, etc. In the winding process, it is very important to accurately measure the height of the material on the roll. It helps the operator to determine whether the roll is full and replace it with a new roll in time to ensure the continuity and efficiency of the winding process.

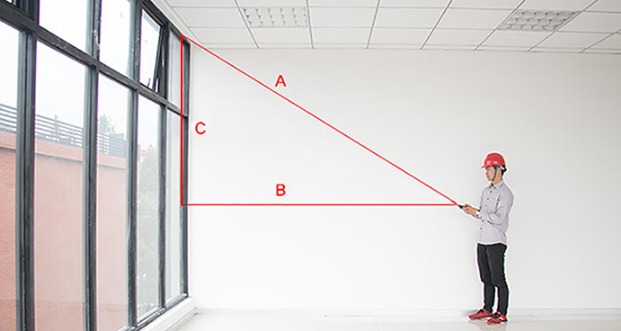

To judge whether the coil is full, traditional measurement methods such as mechanical measurement and optical measurement are usually used. In the face of the update of production equipment and the improvement of work efficiency, these two measurement methods have certain difficulties and limitations. Laser distance measurement sensor is a non-contact measurement device based on the principle of laser measurement. By emitting a laser beam and measuring the time required for it to be emitted from the sensor to the target object and reflected back, the accurate distance of the target object from the sensor is calculated. It can effectively solve these problems.

During the winding process of the film, the height of the material on the roll is measured by laser distance measurement, which can determine whether the roll is full and make necessary changes. The laser distance sensor is installed in a suitable position next to the roll of the film so that it can accurately illuminate the material on the roll. Through the calibration procedure, the distance measurement range and sensitivity of the sensor are adjusted to adapt to the measurement of rolls of different sizes and material heights. Start the winding machine, and the sensor begins to measure the height of the material on the roll in real time and transmit the measurement results to the control system.