Silos come in various types, ranging in height from 10m to 30m. They are usually used by farmers to store animal feed, crop grains, etc. Similar applications include fisheries, construction, mining, and chemical industries. Silos are used to store some raw materials or finished products. Accurately measuring the material level of silos is very important for silo storage in various industries.

In the past, the main method for checking the material level in the silo was for workers to climb to the top of the silo and observe with the naked eye. Workers needed to monitor multiple times a day. Not only was the inspection process full of dangers, it was also very inefficient. The results relied on visual observation and estimation, which was not accurate. Climbing the silo also caused thousands of safety accidents.

With the development of material level monitoring technology, the detection methods of silo material level mainly rely on ultrasonic level meters, radar level meters, laser rangefinders, etc. Some detection methods can only be used as alarm signals, that is, if the material is lower than the material level, the material is replenished in time, and if the material level is higher than the material level, the filling is stopped; some methods are limited by technical principles and have strict requirements on installation conditions; some methods are limited by the measurement height, resulting in high costs. In order to easily obtain real-time remaining information of materials in the silo anytime and anywhere, there is no need to climb the silo on site for inspection, which ensures the personal safety of employees, reduces human errors, and improves the accuracy of silo inspections. In this article, the editor of Motian RF introduces the technical application of laser rangefinders in material level detection solutions.

The working principle of the laser transmitter is similar to that of the ultrasonic transmitter. It will emit a laser beam to the surface of the material. When the laser encounters the surface of the material, it will be reflected back and received by the receiver. By measuring the time of laser emission and reception, as well as the propagation speed of the laser in the air, the height of the material stack can also be calculated.

The laser sensor can detect and feedback data quickly and can measure the inclination angle, but the internal environment of the silo is relatively complex. In order to avoid erroneous data caused by the detection of beams and silo walls, the sensor detection method also adopts vertical detection or fixed small angle detection of the silo, that is, it can only detect data at limited points. Therefore, different monitoring solutions can be adopted:

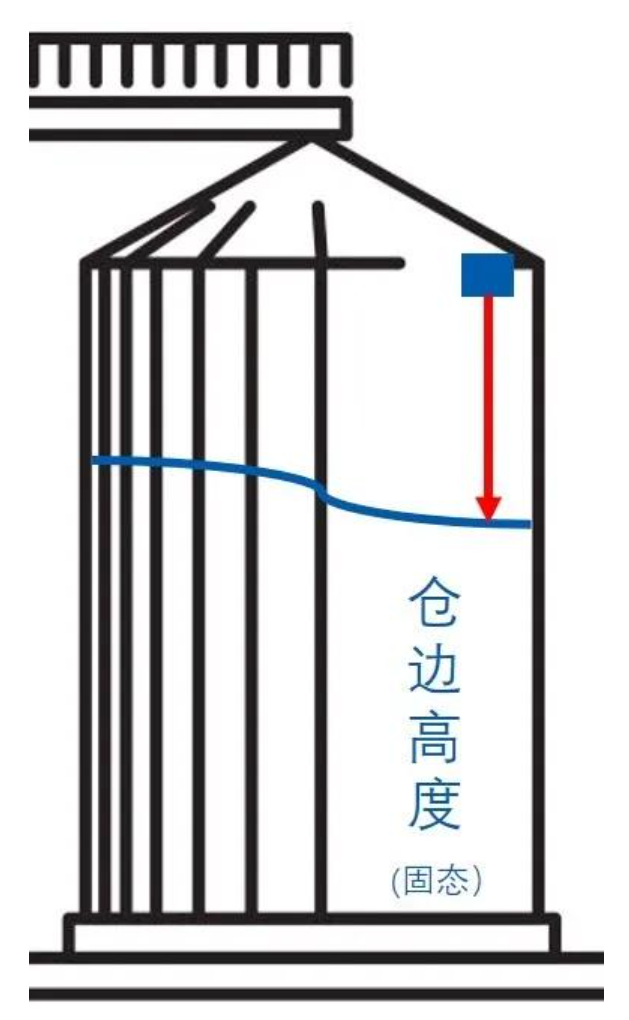

Single-point monitoring: The sensor is installed in the middle of the silo top, and is vertically directed downward to the center of the material pile for measurement, which is used to detect the material level height in the silo;

Multi-point monitoring fixes multiple radars side by side with structural parts. The whole device is installed in the middle of the silo top. The material position is measured by three points to build a material top model, which can easily distinguish the shape of the material top (convex, sunken).

The mounting mode monitoring will be mounted on a tooling with two degrees of freedom. The entire device is installed on the top bevel of the silo. The scanning is used to build a model of the top of the material, and then the volume of the remaining material in the silo is accurately measured.

In order to grasp the material level of each silo in real time to ensure the continuity and stability of the material flow and avoid material shortages and outages, the current silo management system needs to install an expensive weighing platform under the silo to obtain the current position of each silo. This method requires the addition of complex weighing sensors and civil engineering platforms to the silo system, which is not conducive to the maintenance and upgrade of the silo system and greatly increases the construction cost of the silo system. The accurate detection of the real-time position of the silo is a current research hotspot and an effective solution to the problem of material shortages and outages.